The Of Roof Nuts

Table of ContentsThe 6-Second Trick For Roof NutsThe Basic Principles Of Roof Nuts The Only Guide to Roof NutsRoof Nuts Fundamentals Explained

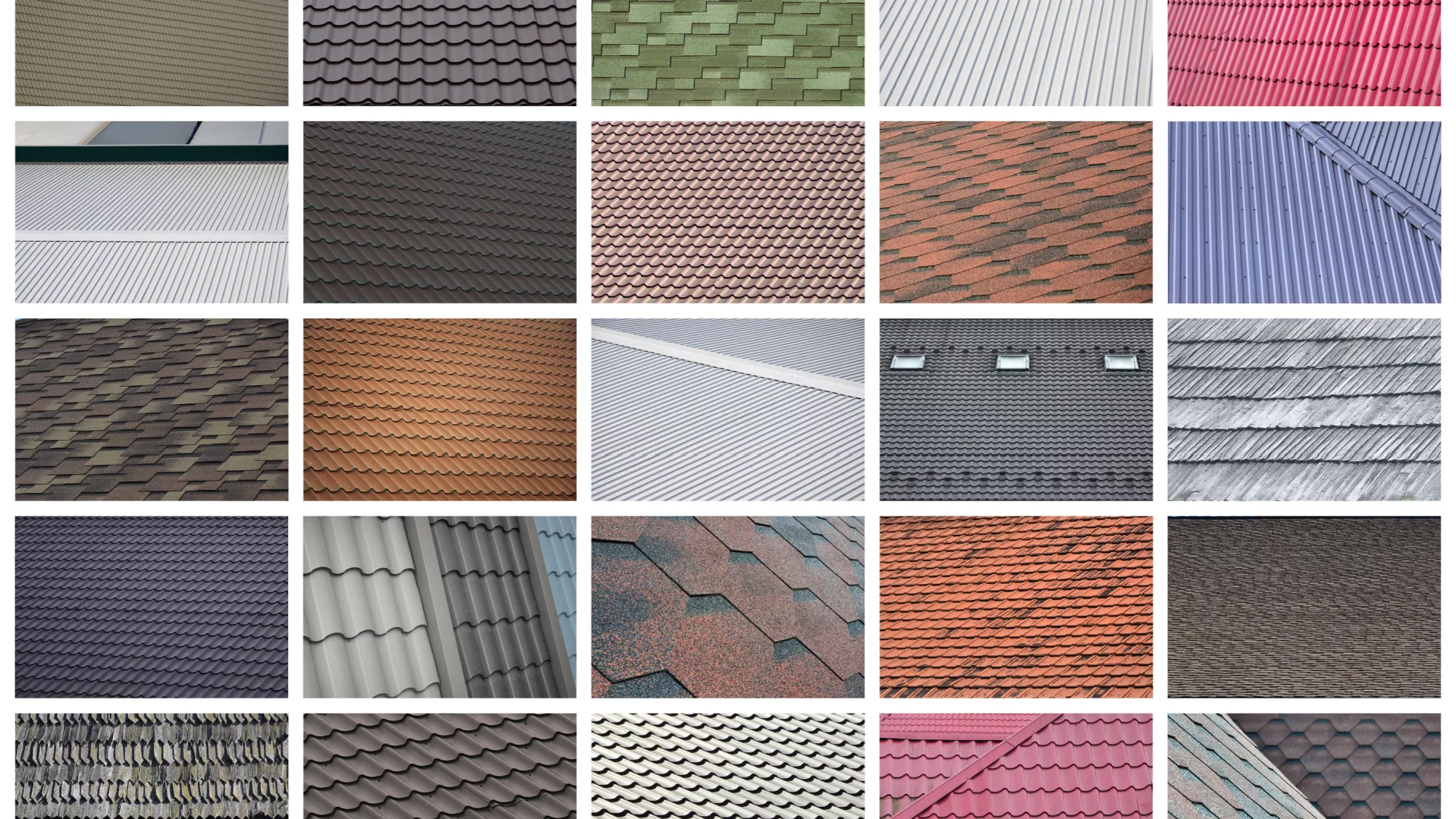

Made from an artificial thermoplastic layer integrated with strengthening scrim, TPO roof covering is mounted using heat welding, producing a solid and durable bond with the roofing system deck. This technique of installment ensures that TPO roofing systems can last as much as 25 years with correct care and maintenance. TPO roofing product is readily available in numerous widths, making it versatile for different level roof covering applications. PVC roofing is not recommended for high inclines, as well as areas with heavy snowfall or freeze-thaw cycles. PVC roof covering incorporates toughness with simplicity of installation, making it a popular selection for different flat roof covering applications.These systems, likewise referred to as built up roof, are composed of numerous layers of asphalt-impregnated roof covering felt and asphalt, developing a robust and watertight obstacle against the components. The leading layer usually features carefully crushed rock granules, offering a wear-resistant surface that can hold up against the rigors of time. The systematic application procedure of BUR assurances correct bond of each layer, thus boosting the roofing's overall durability and long life.

Get This Report about Roof Nuts

BUR is recognized for its cost-effectiveness, providing an affordable expense per year of predicted service life compared to other industrial roof covering systems. With a life-span varying from 15 to 30 years, BUR supplies a reliable and resilient roof service for both domestic and commercial structures. Its capacity to deal with various climate condition and its cost-effectiveness make BUR an attractive choice for several residential property proprietors.

thanks to the addition of special polymers. This asphalt-based material is changed to boost its flexibility and longevity, making it appropriate for a broad variety of climates and applications. Modified asphalt roof covering is produced into rolls with either smooth or granulated surface areas, supplying different options for numerous roofing requirements. There are various sorts of modified bitumen roof, with typical polymers such as atactic polypropylene discover here (APP) and styrene butadiene styrene (SBS) used in the cap sheet.

The cold adhesive technique entails applying a specifically formulated adhesive to the substratum prior to laying down the modified bitumen sheets. There are additionally self-adhesive modified bitumen sheets that feature a pre-applied adhesive layer, eliminating the need for open flames during installment. Each approach has its benefits, yet all need competent specialists to make certain optimal efficiency and durability

Indicators on Roof Nuts You Need To Know

Metal roof coverings can significantly improve the curb allure of your property, making them a prominent option for both domestic and commercial buildings. For level roof coverings, there are primarily two kinds of steel roof coverings: standing seam and screw-down panel systems. Standing joint steel roofings consist of panels secured together at the seams, permitting for expansion and contraction. Steel roofing supplies several advantages, consisting of longevity and durability. Steel flat roof can last as much as 35 years in ideal problems, making it a reputable long-term financial investment. Furthermore, steel roofing systems can swiftly lose snow and ice, protecting against the build-up that can trigger damages. One of the significant drawbacks of steel roofing is its greater initial expense contrasted to other roof products.

Fluid roof covering has a reasonably uncomplicated application procedure that ensures smooth, effective coverage. There are numerous types of liquid coverings used in roof covering, each offering unique benefits: Silicone layers succeed in weather resistance and can stand up to ponding water without deteriorating.

Rumored Buzz on Roof Nuts

The roofing surface have to be completely cleansed and repaired to get rid of any type of particles, dirt, or damaged areas that could impede the finishing's effectiveness. This preparation stage is vital as it sets the structure for a seamless and long lasting roof covering layer. When the surface area is prepared, the fluid covering is commonly used making use of spray devices or rollers for also coverage.

The average life expectancy of a level roof has to do with twenty years, which influences the overall value obtained from the first investment. Labor costs are a considerable component of fixing costs and can substantially affect the long-term value of a flat roofing - https://ro0fnutsga.carrd.co/. Purchasing a durable and long-lasting roof covering material can save money in the future by reducing the frequency and price of repair work and maintenance